L/F Ninmum Flat Bonding Area

L/F 플랫 본딩 영역

RAW MATERIAL

COPPER ALLOY

MEASURING POINT

AT THE POINT OF 0.3mm

FROM LEAD TIP

사MIN. LEAD SPACE

0.05 mm

BOTTOM WIDTH

MIN. 70% OF TOP

(단위: mm)

| THICKNESS/INNER LEAD PITCH | 0.230 | 0.220 | 0.210 | 0.200 | 0.190 | 0.180 | |

|---|---|---|---|---|---|---|---|

| 0.127 | MASS | 0.140 | 0.130 | 0.120 | 0.110 | 0.100 | 0.090 |

| SPECIALLY | 0.145 | 0.135 | 0.125 | 0.115 | 0.105 | 0.095 | |

| 0.152 | MASS | 0.130 | 0.120 | 0.110 | 0.100 | 0.090 | 0.083 |

| SPECIALLY | 0.135 | 0.125 | 0.115 | 0.105 | 0.095 | 0.085 | |

General Etching Dimensional Capabilty

일반 에칭 치수 역량

| Items/Thick | 0.127 | 0.152 | 0.254 | 0.508 | 0.762 | 1.000 |

|---|---|---|---|---|---|---|

| Strip Length | ±0.030 | ±0.040 | ±0.050 | ±0.080 | ±0.100 | ±0.120 |

| Strip Width | ±0.030 | ±0.040 | ±0.050 | ±0.080 | ±0.100 | ±0.120 |

| Strip Pitch | ±0.025 | ±0.025 | ±0.025 | ±0.030 | ±0.030 | ±0.030 |

| STD Pilot Hole Dia | ±0.013 | ±0.025 | ±0.025 | ±0.050 | ±0.080 | ±0.100 |

| Dimple Dia | ±0.040 | ±0.040 | ±0.040 | ±0.050 | ±0.080 | ±0.080 |

| Half Etching Depth | ±0.025 | ±0.025 | ±0.025 | ±0.030 | ±0.040 | ±0.050 |

| External Lead Width | ±0.025 | ±0.025 | ±0.025 | N/A | N/A | N/A |

| Inside Dambar To Dambar | ±0.025 | ±0.025 | ±0.025 | N/A | N/A | N/A |

| Inside Rail To Rail | ±0.025 | ±0.025 | ±0.025 | N/A | N/A | N/A |

| Horizontal Burr | Max 0.025 | Max 0.025 | Max 0.025 | Max 0.025 | Max 0.025 | Max 0.025 |

| Vertical Burr | Max 0.025 | Max 0.025 | Max 0.025 | Max 0.025 | Max 0.025 | Max 0.025 |

| Off Set | Max 0.015 | Max 0.015 | Max 0.015 | Max 0.020 | Max 0.020 | Max 0.020 |

| Coner Radius | Max 0.102 | Max 0.122 | Max 0.203 | Max 0.406 | Max 0.610 | Max 0.800 |

| Coil Set | Max 0.500 | Max 0.500 | Max 0.500 | Max 0.500 | Max 0.500 | Max 0.500 |

| Cross Bow | MMax 0.150 | MMax 0.150 | MMax 0.150 | MMax 0.180 | MMax 0.180 | MMax 0.180 |

| Tie Bar Planarity | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 |

| Lead Tilt & Twist | Max 2.5˚ | Max 2.5˚ | Max 2.5˚ | Max 2.5˚ | Max 2.5˚ | Max 2.5˚ |

| Lead Planarity | Max 0.080 | Max 0.080 | Max 0.080 | N/A | N/A | N/A |

| Pad Tilt | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 |

| Pad Planarity | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 | Max 0.080 |

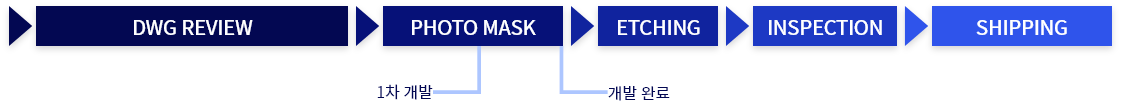

FAI&MASS Production Cycle Time

FAI&MASS 생산 주기

| DESCRIPTION | 1일차 | 2일차 | 3일차 | 4일차 | 5일차 | 6일차 | 7일차 |

|---|---|---|---|---|---|---|---|

| FAI ORDER |

|

||||||

| REPEAT ORDER |

|

||||||